About the CAS

Entering a new era of CAS precision freezing

Why not introduce the latest precision freezing technology CAS?

CAS is ideal for building quality in the following fine food industry, where quality and precision are required

Food markets and restaurants

Food markets and restaurants Hotels and inns

Hotels and inns Food processors

Food processors Production area operators

Production area operators

The introduction of “CAS” precision freezing technology can create convenient and active evolution of food.

Now is the time to create new markets.

Purchasing, which was previously driven by quality and price concerns, can evolve into strategic purchasing such as purchasing in bulk when the market is stable and preserving high quality.

Significant reduction of food wastage

The system provides an environment wherein high-quality food ingredients with short production lives can be utilized in a stable, reliable, and economical manner.

Peak shaving in food production

The production system can now shift from conventional centralized production, which requires large quantities of products to be obtained immediately before the sales season,

Expansion into mail-order and export business

Ingredients and food of the same quality may now be delivered to any location, regardless of time or distance. Moreover, taking on the challenge of establishing new sales channels is now possible.

Prevention of lost opportunities due to shortages, etc.

Stocking a larger number of high-cost dishes that could only be prepared in small quantities due to fear of waste is now plausible.

Security of a versatile menu

Restaurants may now diversify their menu to differentiate from other restaurants and offer a wider selection of products at low risk. This means that restaurants can focus on food production and enhancing quality.

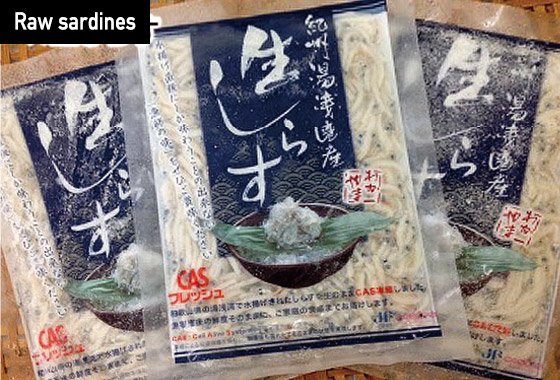

Freshuness becomes an asset with the introduction of CAS

CAS enables the long-term storage of freshness,

which was impossible with conventional quick freezing.

Unique technology that makes a difference in quality

Abi has developed precision freezing by integrating ice crystal formation suppression technology, which is necessary to bring foodstuff to a stable frozen state, into a unique control board.

The transmitter for installation inside the freezer, controlled by the CAS-Engine, precisely deploys a special AC magnetic field energy environment inside the quick freezer to physically prevent the crystallization and uneven distribution of water molecules that occur during freezing. Moreover, it allows foodstuff to be stably brought to a frozen state.

Eliminating degradation will make

the food industry stronger from the inside out.

Simultaneous solves the problems of risk and waste.

Not bound by time or distance.

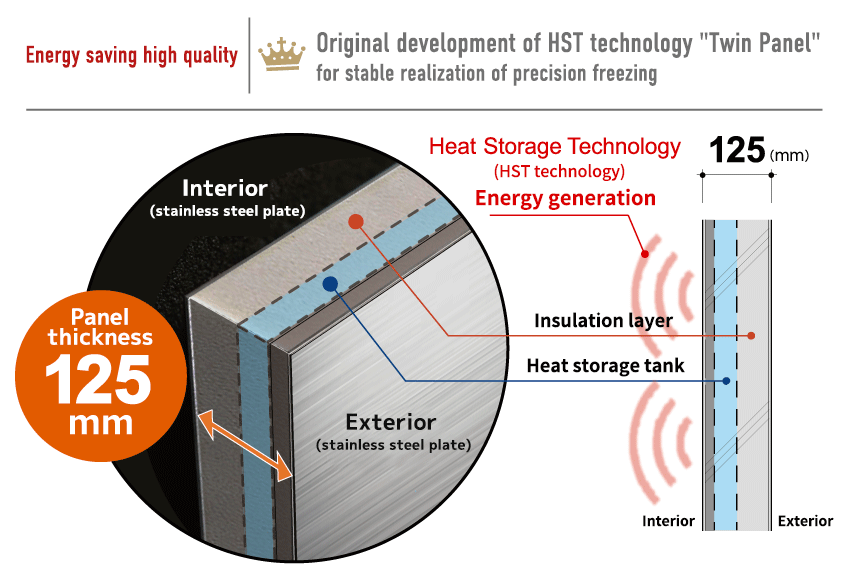

More horsepower with less revving

means a lower cost, which is beneficial

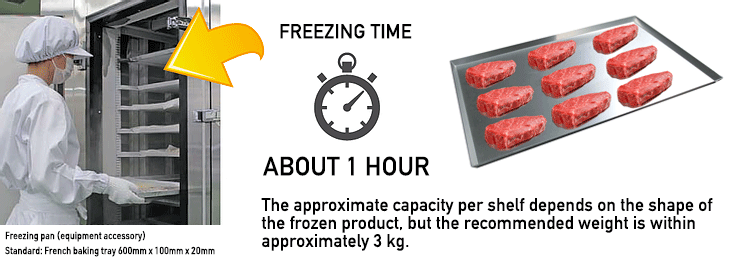

The freezing machine is subjected to a large load intermittently during the freezing process, such as when the door is opened and closed or when unfrozen products are placed inside the device. However, the use of the originally developed panel with a built-in thermal retention layer means that these fluctuations can be gently absorbed.

It also achieves lower electricity costs and higher product quality in an agile manner by turning on the high-powered compressor only when necessary.

The introduction of CAS precision freezing technology

will revolutionize the food industry as we know it.

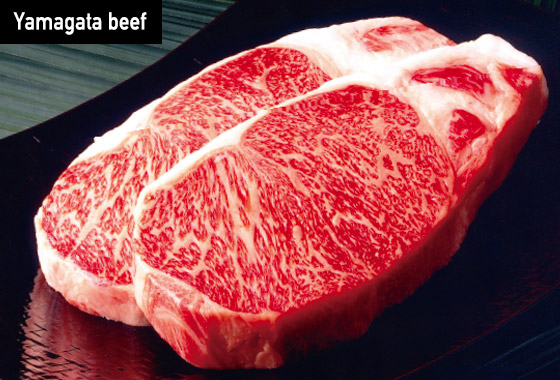

Meat products

Food that “can only be eaten here” can now be transported anywhere. Limitless expansion of limited trading areas

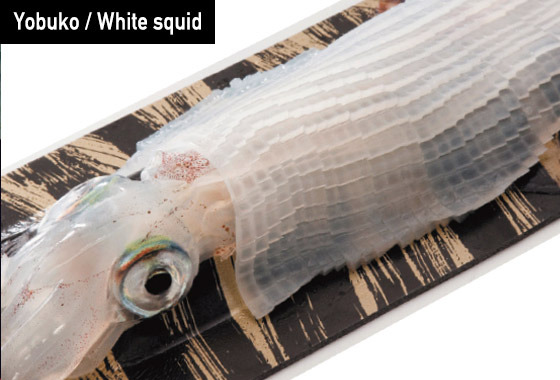

Cooked quality seafood

“Stored fresh” becomes an option. Management stability through high quality and elimination of waste

Seasonal products

Systematic strategic use of seasons Surprise your customers with special products.

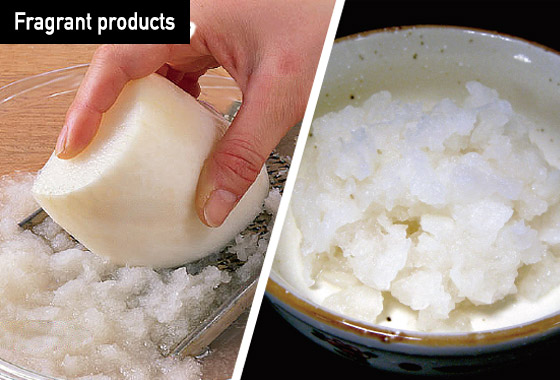

Fragrant products

Fragrant products, such as grated white radish and condiments, can be stored for a long period while maintaining their delicate aroma and fresh texture

French cuisine

French cuisine, cooked products, or “freshly made” products can be stably supplied with high quality and without waste.

Kyoto kaiseki cuisine

Kyoto kaiseki cuisine and prepared products, including sashimi, gelatin, and starchy sauce, which are considered difficult to freeze, can be frozen as is.

Lengthens short expiration dates

With a small amount of additional freezing time, the flexibility of the ingredients is dramatically increased.

Various types of equipment are available depending

on the size of the business.

5 tray batch type

(Freezing ability: 15kg/h)

10 tray batch type

(Freezing ability: 30kg/h)

20 tray batch type

(Freezing ability: 60kg/h)

Various rack types

(Freezing ability:60kg or over/h)

We will set up the best possible machine for the location of installation.

Various tunnel types

We will engineer and manufacture various designs for full-scale mass production, including for loading fishing boats such as tuna boats.

Various spiral types

The precision freezing CAS engine can be retrofitted to existing quick freezers.