About the CAS CASとは?

About the CAS Engine

The “Cells Alive System (CAS)” is a technology

that manages water molecules to ensure cell tissues are intact

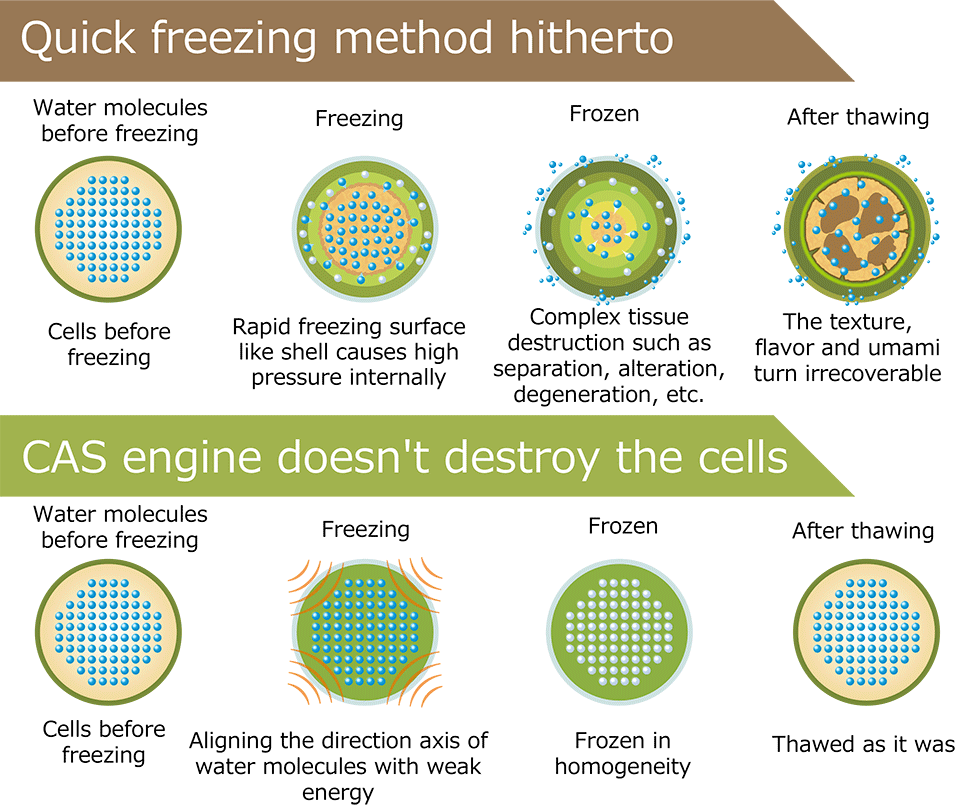

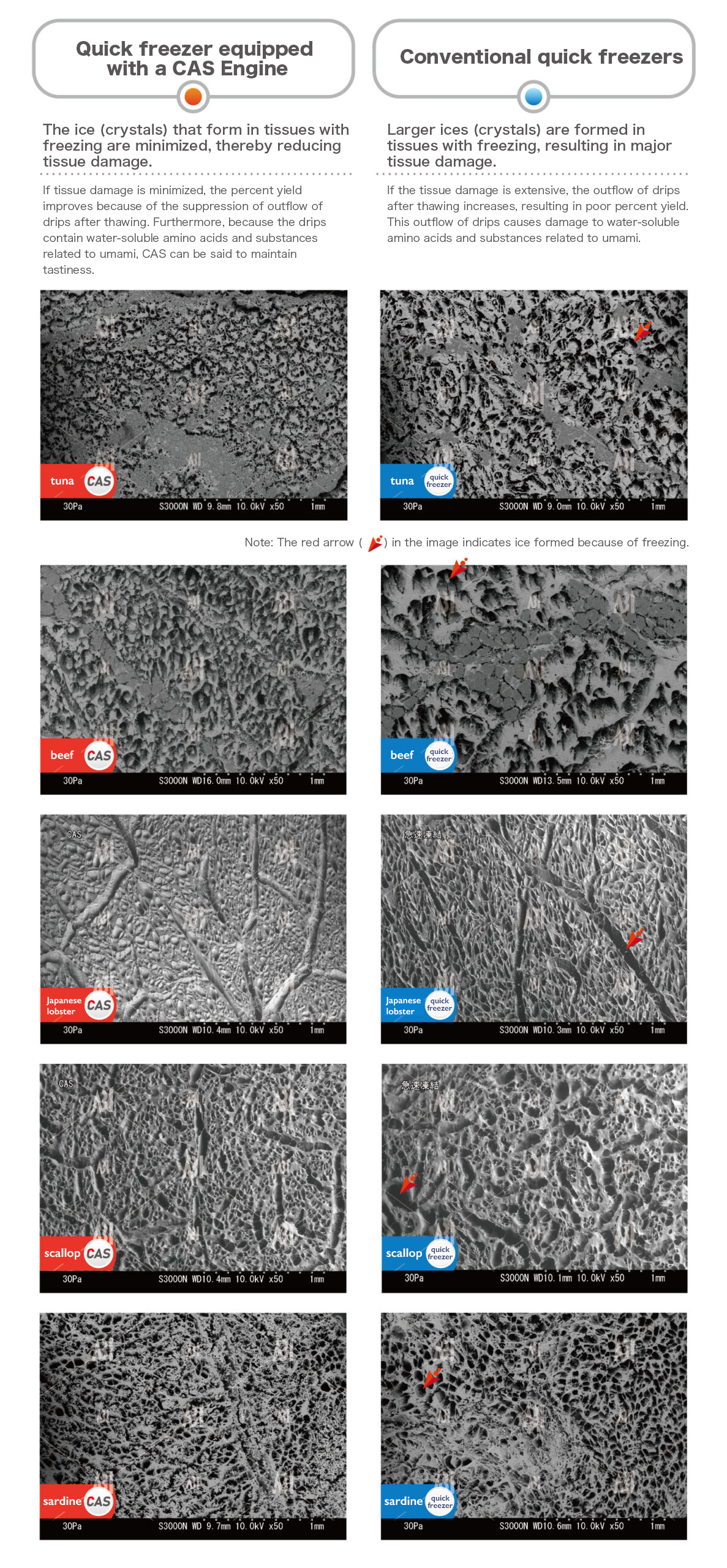

Within the freezer, a special CAS generator is used to uniformly apply eight combinations of CAS energy to cell tissues, thereby vibrating the water molecules within cell tissues. In this manner, the ice crystals that are formed are refined without water collecting and these crystals freeze while protecting the cell walls and cell membranes of food. As the world’s first revolutionary technology of its type, the CAS Engine is currently being used in a broad range of fields from food to medicine and applied physics.

CAS is registered as a trademark by ABI Co., Ltd.

Please beware of products that imitate CAS.

The “CAS Engine” reproduces the same tastiness of food before freezing.

The CAS engine uniformly maintains the water molecules in ingredients (e.g. agricultural products, seafood, meat, and other food products in dishes) by a weak electric current. Conventional quick freezers bring water molecules expanding and it destroys cell membrane. And drip ends up flowing out, the deliciousness of the food stuff is lost after thawing. The CAS engine equipped inside the conventional quick freezer can generate a magnetic field inside the chamber. As a result, foods can return to the same as “raw” before freezing because of preventing water molecules expanding, minimizing cell membrane destruction as much as possible.